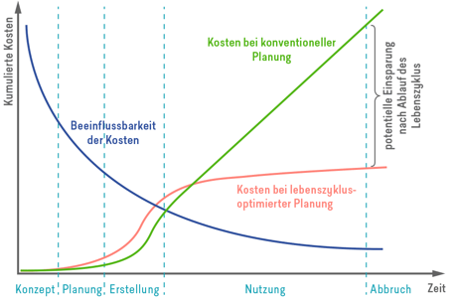

Cost argument

Which isolation system should be used increasingly depends on operating costs.

Energy-efficient and environmentally friendly products are the most cost-effective option in many ways, especially in view of all the costs that are incurred over the life of a product (life cycle cost). Like our moisture-tight insulation materials for train construction, which provide optimal thermal and acoustic isolation.

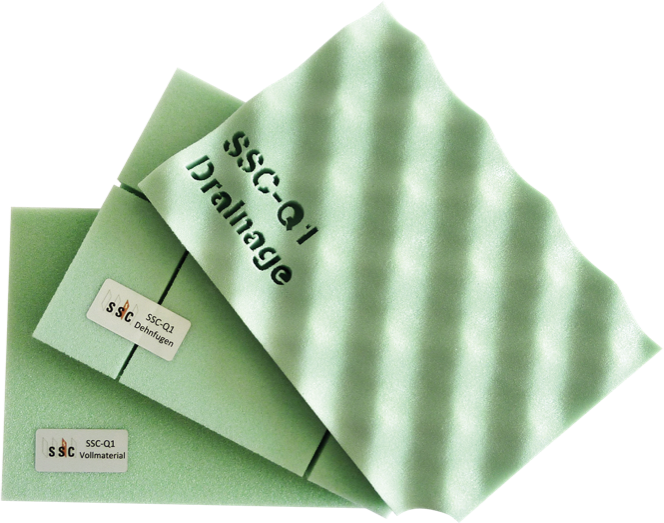

SSC-Q1

Our all-rounder – a high performance isolation material made of closed-cell polyethylene foam. We developed this product for the needs of the rail sector and applied for a patent jointly with the SSC assembly system.

The advantages

- Simple assembly

- Suitable for all climates

- No rear ventilation necessary

- Space-saving and weight-saving

- No corrosion problems

- Hygienic material properties

- Permanent prevention of moisture absorption, making condensation inside the isolation impossible

- Certified fire protection in accordance with EN 45545-2 R1 (HL 3), GOST, NFPA 130

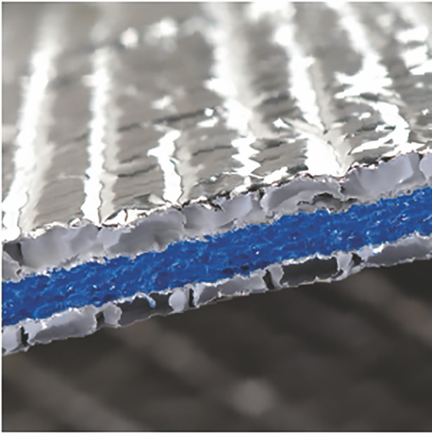

SSC-Q20

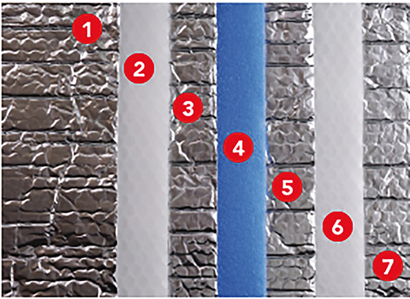

An almost impermeable barrier for infrared radiation – our ultra-thin, multi-reflector, multi-layer and full-surface heat-sealed insulation, consisting of multiple aluminium layers and polyethylene materials for perfect thermal isolation.

The advantages

- Condensation is impossible in the indicated temperature range

- Simplified isolation of air ducts

- Fire safety standard EN 45545-2, requirement set R1 (HL3), NFPA 130 and GOST

- Life cycle > 30 years

- Air- and water-tight

- Certified fire protection in accordance with EN 45545-2 R1 (HL 3), GOST, NFPA 130

- Simple processing and assembly

- Space-saving

- Oxidation-resistant pure aluminium foil, 30 microns thick

- Fire-resistant PE foil, with enclosed dry air

- Oxidation-resistant pure aluminium foil

- Fire-resistant and water-repellent polyethylene foam

- Oxidation-resistant pure aluminium foil

- Fire-resistant PE foil, with enclosed dry air

- Oxidation-resistant pure aluminium foil, 30 microns thick

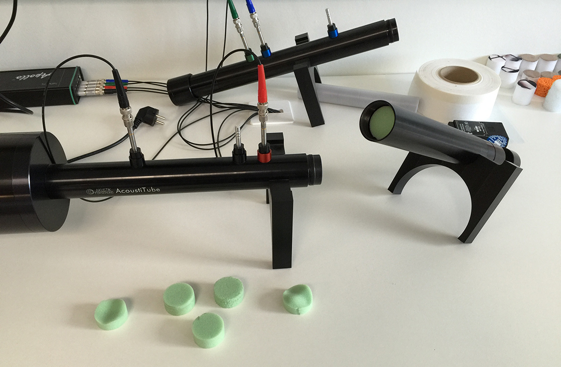

Test set-ups by SSC and Bosig Acoustic measurement facility

Railcar body isolation

For optimised railcar body isolation, we calculate the minimum material strengths for the floor, side wall, and ceiling isolation materials. The calculation is based on the laboratory values of isolation materials with regard to heat transfer and U-values, all tested in-house.

Our centre of excellence not only has laboratory facilities and accredited analysis methods, but experienced specialists as well. Their expertise lies in the fields of foams and plastics, fire behaviour, energy and technology and in thermal construction optimisation and analysis.

Sample installation and

use

Economics and

sustainability

When selecting the optimal isolation design, taking a holistic view is a good idea for both economic and ecological reasons. For rail operators, energy costs for heating, ventilating, and cooling the vehicle are of primary importance.

Choosing our innovative and future-proof isolation ideas brings advantages in every respect – and thanks to the use of unproblematic materials and reduced CO2 emissions, the environment benefits, too.

Would you like some advice?

We would gladly take the time to present you with an innovative solution.

+49 (0)711 5056 48 30

Consulting